- Details

-

Features

▎Enrich the auxiliary function of parameter adjustment, and put new varieties into production more easily

▎Safe production by monitoring equipment status

▎High -quality optical system to improve image recognition performance

▎Reduce ineffective actions during welding and improve UPH

▎Standardization of optional functions and easy-to-operate functions improve operability

▎Fail -safe function can prevent damage caused by misoperation and equipment abnormality

Application Scenario

Capillary Wedge Bonding (CWB)

NAND flash memory is widely used in memory media from USB storage to cloud servers. In order to increase the capacity, multiple chips are usually welded together. The signals of the multi-segment overlapping chips are transmitted by the welded metal thin wires. Generally speaking, welding the corresponding number of segments and repeatedly cutting the welding wires is a very time-consuming and laborious task, which has become a bottleneck for improving productivity.

In response to this, Shinkawa has developed Capillary Wedge Bonding (CWB) technology, which can continuously weld multiple segments without cutting the metal wire. Through this technology, it is expected to shorten the single-piece working time with an absolute advantage. Shinkawa will continue to improve this technology in order to enable more customers to use it.

From "Connection" to "Processing and Creation" Wire Bonding Machine as Electronic Component Manufacturing Machine

Wire bonders are widely used devices for connecting metal wires that can conduct electrical signals. There is still room for further development.

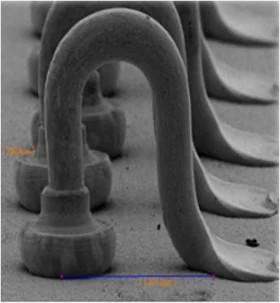

From a large number of "connection" experiences, it is known that metal wires can be arbitrarily controlled. By effectively utilizing this characteristic, it is possible to realize the production of coils, which are important components of electronic components, and ultimately achieve the evolution of electronic component manufacturing equipment. For example, a specific number of coils can be produced, and supplementary coils can be produced for the purpose of loop adjustment.

Shinkawa will continue to make new attempts and challenges now and in the future based on wire bonders.BIM: Bond Inspection Measurement (bond ball position detection function)

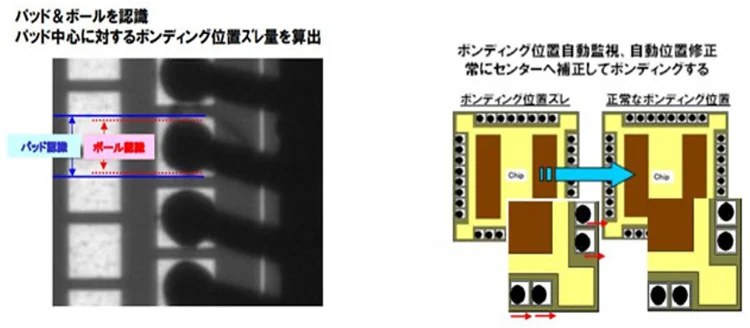

BIM is a function that calculates the offset of the welding position from the image after welding, and then performs welding position correction. It corrects the position offset caused by various changes during welding in real time, and pursues the stabilization of welding accuracy.

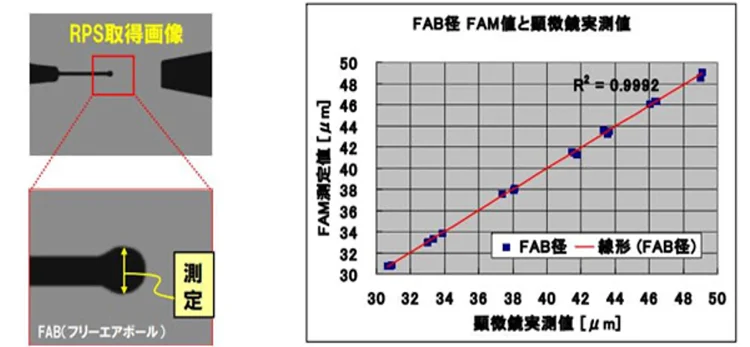

FAM: Free Air ball Measurement (initial ball automatic monitoring function)

FAM is Shinkawa's own function that stabilizes the initial ball shape by monitoring the diameter and shape of the initial ball of the welding wire. For inspection, this function called Reference Positioning System (RPS) can be effectively used to take a picture of the position of the front end of the splitter. This is also a function that supports the high-reliability welding of the UTC-5000 series.