- Details

-

Features and characteristics

▎Based on the UTC-5000 wire bonder, high-speed welding of 30 ms/bump is achieved

▎Equipped with a rotating wafer table, capable of welding 3-6 inch wafers

▎Use dual wafer stages and temperature control functions to shorten wafer replacement time and improve production capacity

▎ Stable soldering of 45μm pad pitch is possible through low-vibration high-speed drive based on Shinkawa NRS technology

▎By adopting Shinkawa RPS technology, the position of the blade tip can be automatically calibrated to achieve high-precision welding position and reduce the workload when replacing the blade

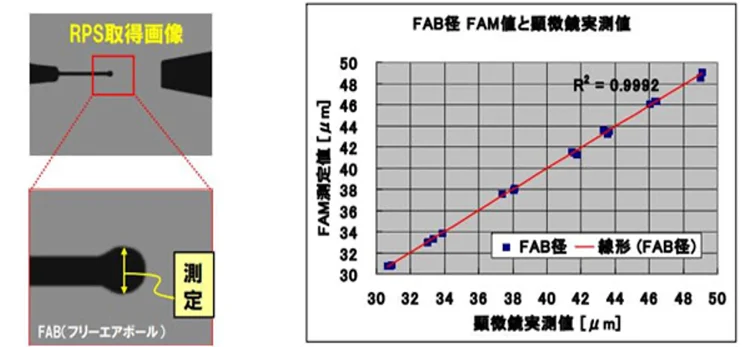

▎The initial ball diameter can be measured through the initial ball diameter automatic monitoring function (FAM)

▎Add a "load detection mode" to the ground detection method during welding, which can detect load changes in real time.

▎Set the previous "position detection mode" to optional to ensure stable quality

Application Scenario

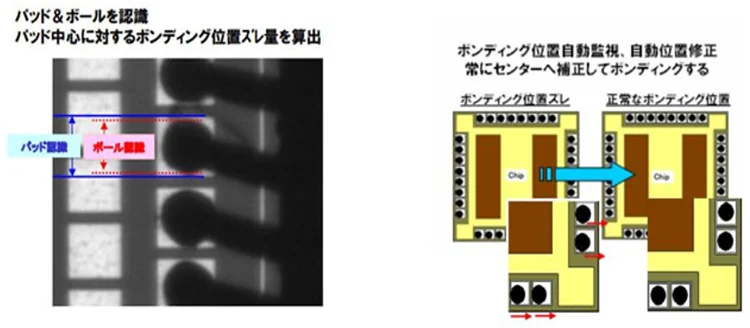

BIM: Bond Inspection Measurement (bond ball position detection function)

BIM is a function that calculates the offset of the welding position from the image after welding, and then performs welding position correction. It corrects the position offset caused by various changes during welding in real time, and pursues the stabilization of welding accuracy.

FAM: Free Air ball Measurement (initial ball automatic monitoring function)

FAM is Shinkawa's own function that stabilizes the initial ball shape by monitoring the diameter and shape of the initial ball of the welding wire. For inspection, this function called Reference Positioning System (RPS) can be effectively used to take a picture of the position of the front end of the splitter. This is also a function that supports the high-reliability welding of the UTC-5000 series.